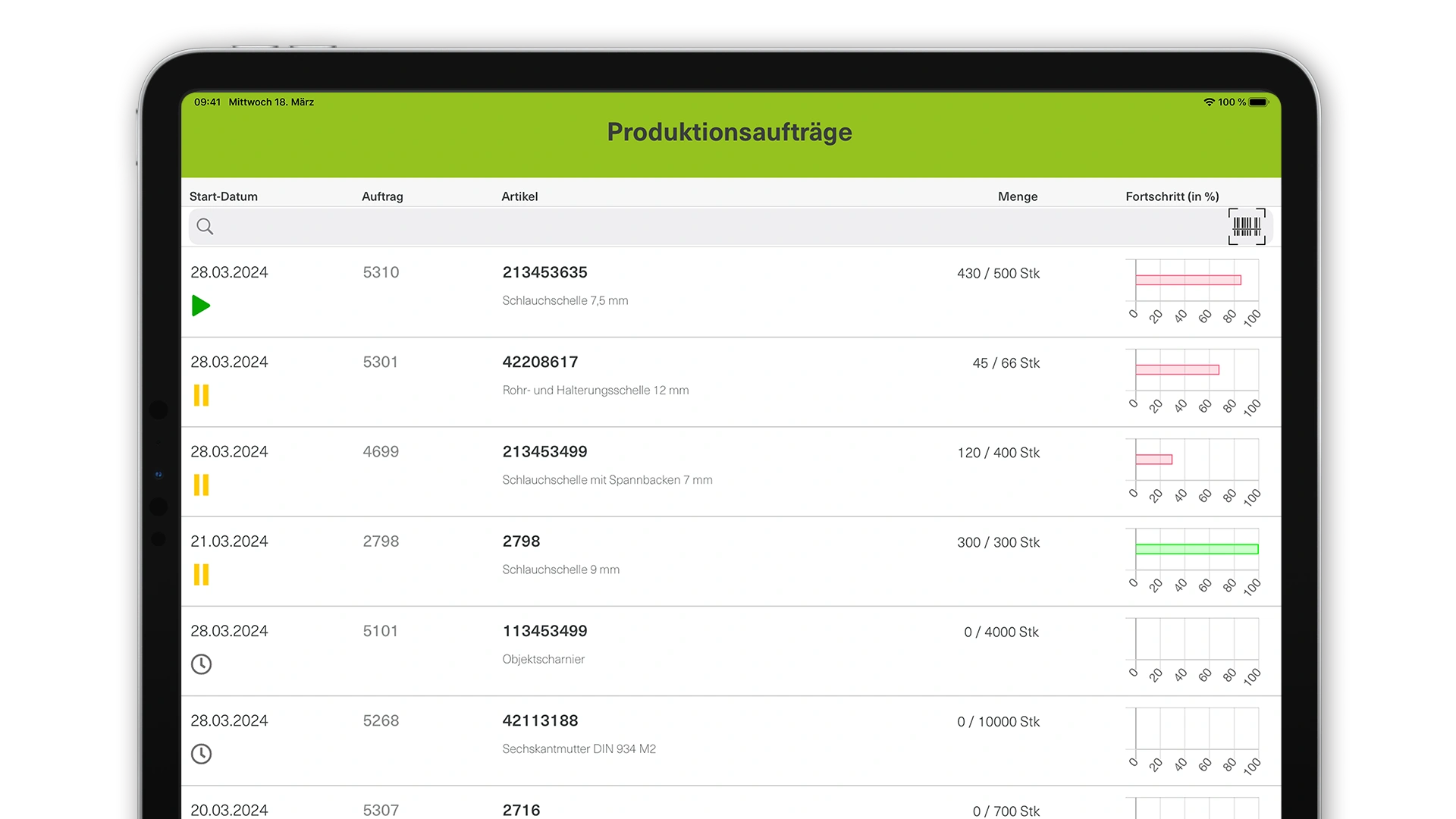

Paperless production

With engomo, we are realizing our ‘paperless production’ project - we couldn't imagine a more flexible platform for this.

Markus Münch

INGUN

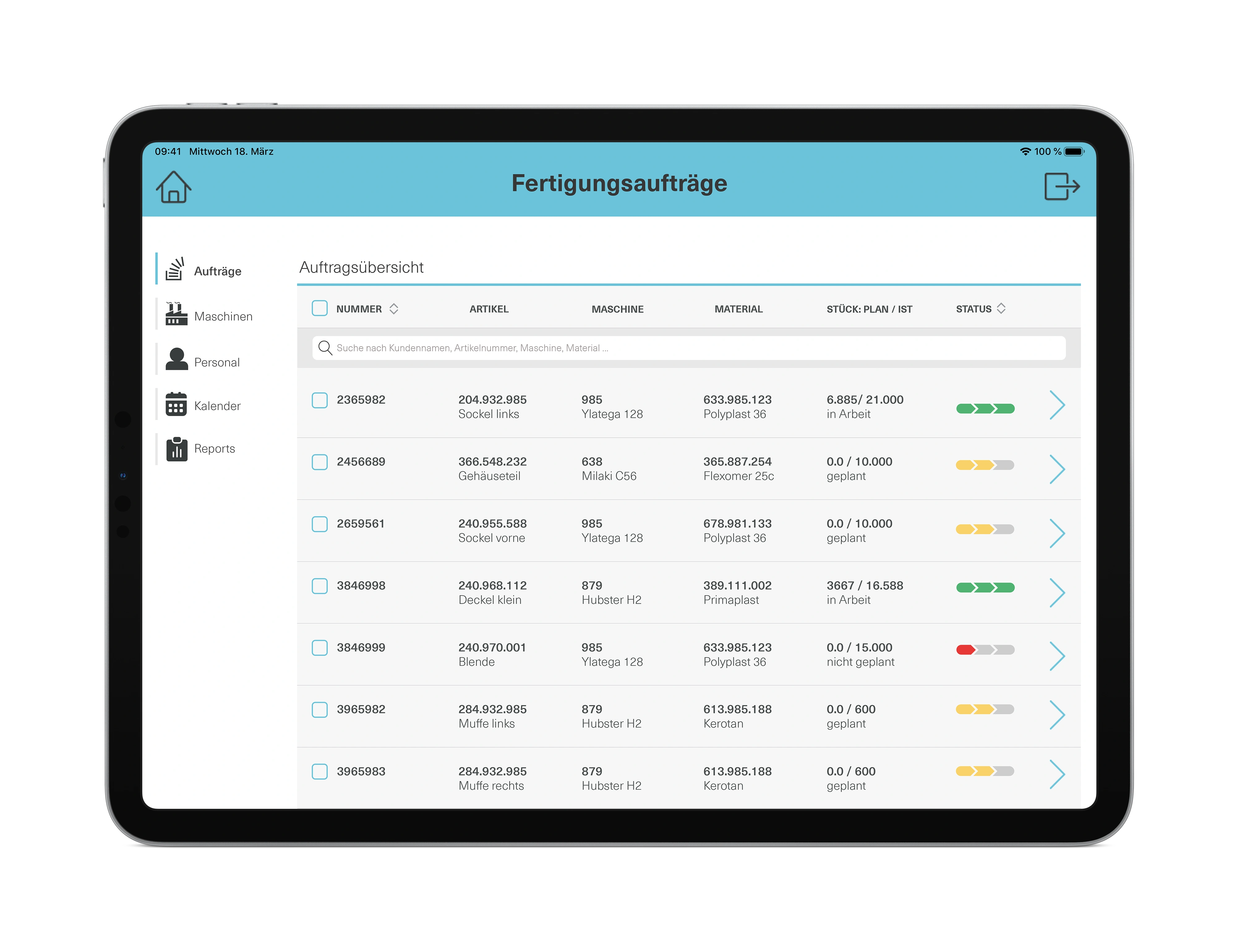

Simplicity that convinces

We configure all our apps ourselves with engomo and our team is more than enthusiastic about the platform's ease of use.

Michael Hasler

Aproxera

Slim. Safe. Efficient

No matter in which area of the company - with engomo, every process can be made leaner, more secure and more efficient.

Frank Schick

RHEINTACHO

Everything in view

With engomo, the local sales force can see immediately whether we have a product in stock and what delivery we are expecting from Paul Mitchell in the USA.

Noah Wild

Wild Beauty GmbH

![Tablet view of an engomo app displaying detailed information for the vertical milling machine [M1]: Shows master data, technical specifications, current status, manuals, and an option to report issues.](https://engomo.com/~/assets/images/Maschinen-Informationen.webp?v=-4538336)